Vacuum Transfer System For Powder

Vacuum transfer system for powder. When producing food pharmaceuticals and chemical products there are demands on the highest possible degree of safety as to hygiene and operation. Vacuum Conveyors is an easy and high-efficiency method of Transferring moving conveying fine chips powders Granulated material Spice powders Food powdersmedical Capsules and other Small particles in an enclosed system and Clean Hygienic manner. Dense Phase Pneumatic Conveying System.

Piabs vacuum conveying systems are built of high quality material. Vacuum is used with great advantage in conveying dry powder products through dedicated pipe systems. Where it is shredded homogenized and stored for later collection.

One of which is its ability to deliver efficient dust control advantage. Find a distributor in your area or contact us for more information about our products. The vacuum transfer system is used in Pharmaceutical Food.

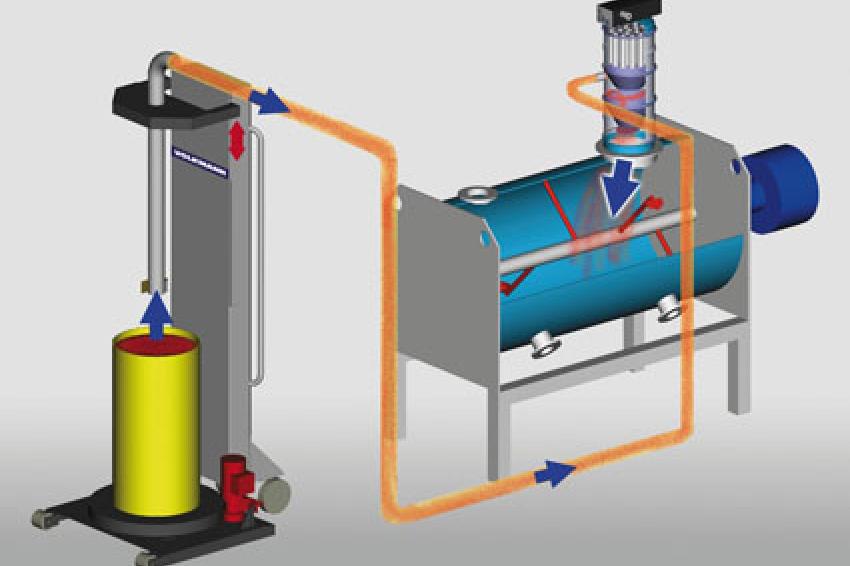

The principle of vacuum transfer has been proven to be a better way to move many types of material and a giant step over manual handling. The 100 material can be easily transferred from one process to another in time with minimum engagement of human resources. Mixers mills dryers batching machine bin etc and.

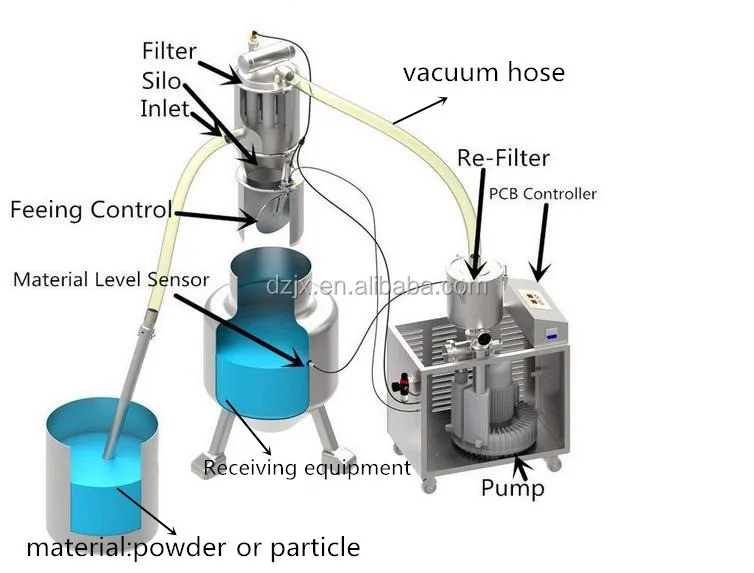

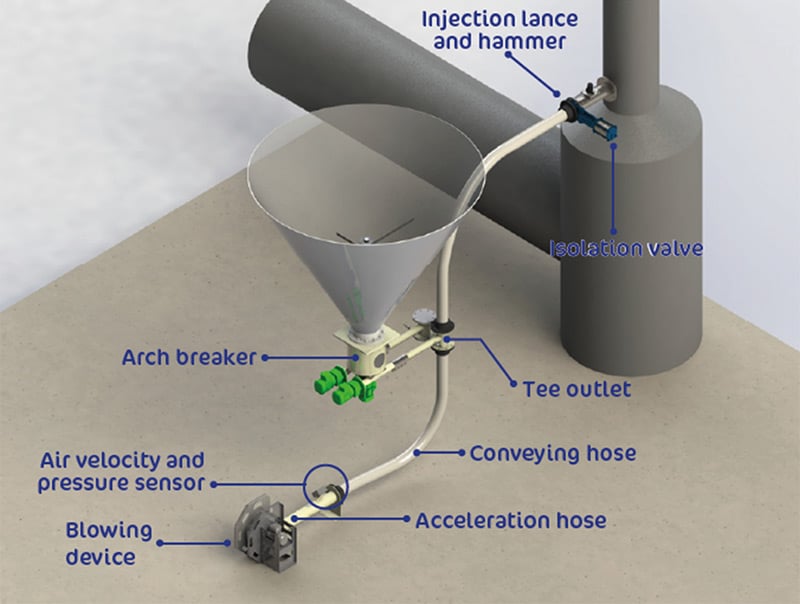

The Vacuum transfer system designed specifically for the direct charge loading of blenders mixers sifter milling reactors or any vessel capable of withstanding a vacuum A Powder loader is provided for machines vessel not capable or facilitate to create vacuum. Most Vacuum Conveying System transfer product based on a timed interval to the vacuum receiver. The vacuum transfer system for powder comprises a suction device vessel with automated valves regeneration type filter a vacuum pump intermediate piping fittings and a control panel.

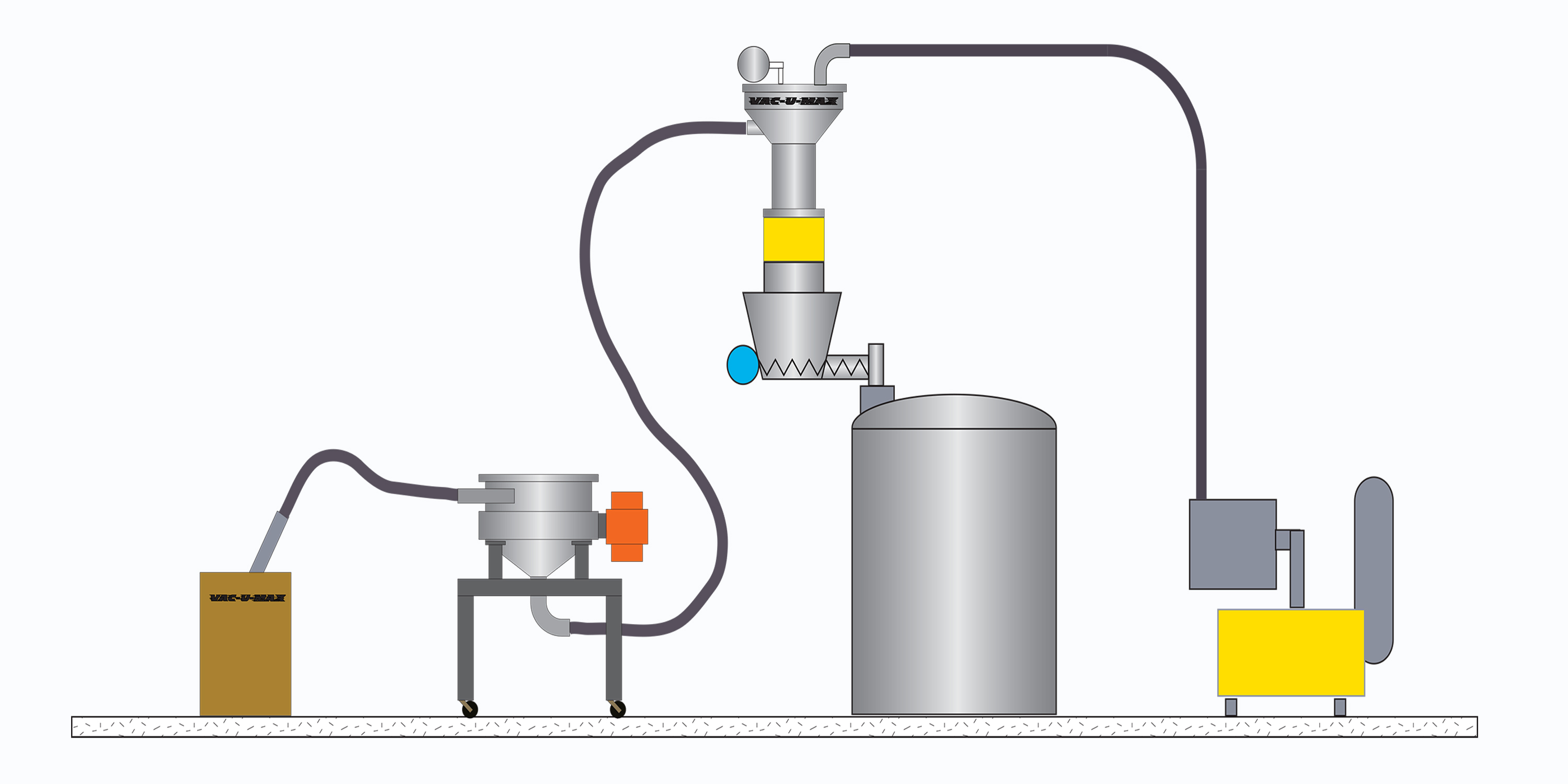

Application Process. This is typically used to transfer powders from containers drums bag dump stations bulk bag unloaders feed hoppers etc to a receiving vessel for further processing. These systems are designed with performance and hygiene in mind making them suitable for use in high-integrity applications such as pharmaceutical food chemical and nuclear projects.

Pneumatic Powder conveying system or hopper loader are transferring powder from one place to another place in bulk quantity. Vacuum Conveying uses suction to transfer dry materials powders granules etc from one location to another within a processing area.

A vacuum conveyor transports the waste material to a receiving container.

The vacuum transfer system for powder comprises a suction device vessel with automated valves regeneration type filter a vacuum pump intermediate piping fittings and a control panel. Allowing waste to be reprocessed to manufacture biogas animal feed or fertilizer. When producing food pharmaceuticals and chemical products there are demands on the highest possible degree of safety as to hygiene and operation. Ad Ideal for floors and fixtures and around lathes saws mills and industrial equipment. Vacuum transfer systems for powder and bulk materials conveying is the preferred transfer method for many industries for a variety of reasons. Vacuum Conveying uses suction to transfer dry materials powders granules etc from one location to another within a processing area. Where it is shredded homogenized and stored for later collection. Application Process. The Vacuum Conveyors are manufactured and used in the pharmaceutical chemical and food Industries for the transfer of powder and grains.

The principle of vacuum transfer has been proven to be a better way to move many types of material and a giant step over manual handling. The 100 material can be easily transferred from one process to another in time with minimum engagement of human resources. Vacuum transfer systems for powder and bulk materials. The Joint Venture has successfully launched more than 100 models different types of vacuum transfer system for powder pharmaceutical vacuum transfer system powder transfer equipment vacuum conveying system and design vacuum conveyor belt system vacuum transfer chemistry vacuum conveyor design pneumatic powder transfer system vacuum system mobile vacuum system. The principle of vacuum transfer has been proven to be a better way to move many types of material and a giant step over manual handling. The material is transferred in a network of tubing from the pick up point or source to the customers process. Hanningfield supply a range of vacuum conveying systems the Uni-Vac series for the fast and contained transfer of powders granules flakes and pellets.

Post a Comment for "Vacuum Transfer System For Powder"